Types of Cracks in Concrete Driveways: Insights from Denver Concrete Driveway Pros

Your driveway is like a red carpet for your home. It deserves attention and care.

But cracks can still creep in over time. No one likes seeing those pesky lines messing up a smooth surface. But not all cracks are the same.

Some are harmless, while others scream, “Fix me now!” So let Denver Concrete Driveway Pros break it down for you and help you spot what’s happening to your concrete driveway.

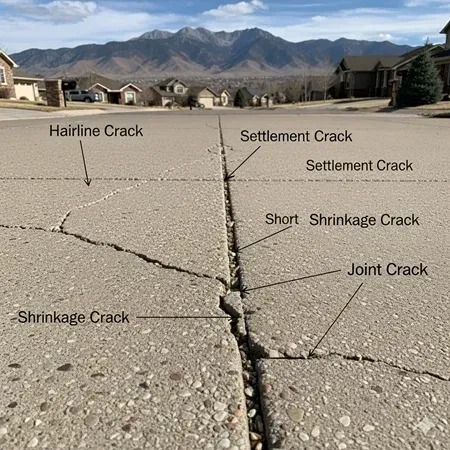

Hairline Cracks (The Annoying Little Guys)

These are tiny and surface-level cracks.

They sneak in shortly after the concrete is poured. Hairline cracks are caused by shrinkage when the concrete loses moisture. They might not seem like a big deal at first. But over time, water can sneak in and wreak havoc.

Don’t ignore them. Water can seep in, freeze during winter, and make the cracks worse.

Seal these tiny troublemakers before they invite their friends.

Shrinkage Cracks (The Drying Drama)

Concrete shrinks as it dries. If it dries too quickly, cracks form.

These cracks don’t scream “disaster.” But they can make your driveway look aged before its time.

The solution? A slow, even curing process. Keeping the concrete moist for days after pouring can stop shrinkage cracks before they start.

Settlement Cracks (When the Ground Can’t Handle It)

Settlement cracks show up when the soil beneath your driveway shifts.

Or if it isn’t packed down well. This causes uneven sinking. As a result, it leads to jagged cracks that widen over time.

To prevent this, the ground beneath your driveway needs solid prep work. If you already have settlement cracks, it’s time to call the pros for a fix.

Heaving Cracks: The Uprising Trouble

Heaving cracks occur when concrete moves upward.

It happens because of freezing and thawing cycles or tree roots. Think of the ground expanding and contracting as temperatures change. It’s a workout your driveway didn’t sign up for.

Pro tip? Relief cuts in concrete slabs can help absorb the pressure and prevent heaving cracks.

Structural Cracks (The Big Trouble)

These are the serious ones. Wide cracks can go all the way through the concrete.

Structural cracks compromise the strength of your driveway. Heavy loads, poor construction, or bad materials often cause them.

They’re the driveway’s way of crying out for help. Noticed cracks wider than 1/8 inch? It’s time to call in the pros. Denver Concrete Driveway Pros can fix these serious cracks and give you practical prevention tips.

Crazing Cracks (The Spiderweb Effect)

Crazing cracks look like a web of fine lines. They usually form when the surface of the concrete dries too quickly.

The good news? These cracks are mostly cosmetic. The bad news? They’re hard to avoid if the pouring or finishing process isn’t handled right.

While they don’t ruin the strength of your concrete, they can make it look, well, messy. Want to avoid them? A slow curing process works wonders.

Expansion Cracks (Concrete’s Growing Pains)

Concrete doesn’t like extreme heat. It expands in the summer.

And it contracts in the winter. Cracks can form if there’s no room to move. Without expansion joints (those intentional grooves), the stress creates cracks.

Properly placed joints allow the concrete to flex. It won’t let it crack. So, keep an eye on these areas. Plus, ensure they’re well-maintained.

Freeze-Thaw Cracks (Winter’s Revenge)

In places like Denver, freeze-thaw cycles are brutal on concrete. Water gets into small cracks and freezes or expands. This makes those cracks bigger.

Sealing your driveway before winter can help protect it. Think of it as putting on a winter coat for your concrete.

Chemical Reaction Cracks (The Reactive Saboteurs)

Concrete can crack due to chemical reactions within or on its surface.

The most common culprit is the alkali-aggregate reaction (AAR). This happens when certain materials in the concrete react with water.

- Alkali-Silica Reaction (ASR): This creates a gel that expands and cracks the concrete.

- Alkali-Carbonate Reaction (ACR): This less common reaction also causes expansion and cracking.

The solution? Avoid adding too many reactive materials to the concrete mix. It will help prevent these issues.

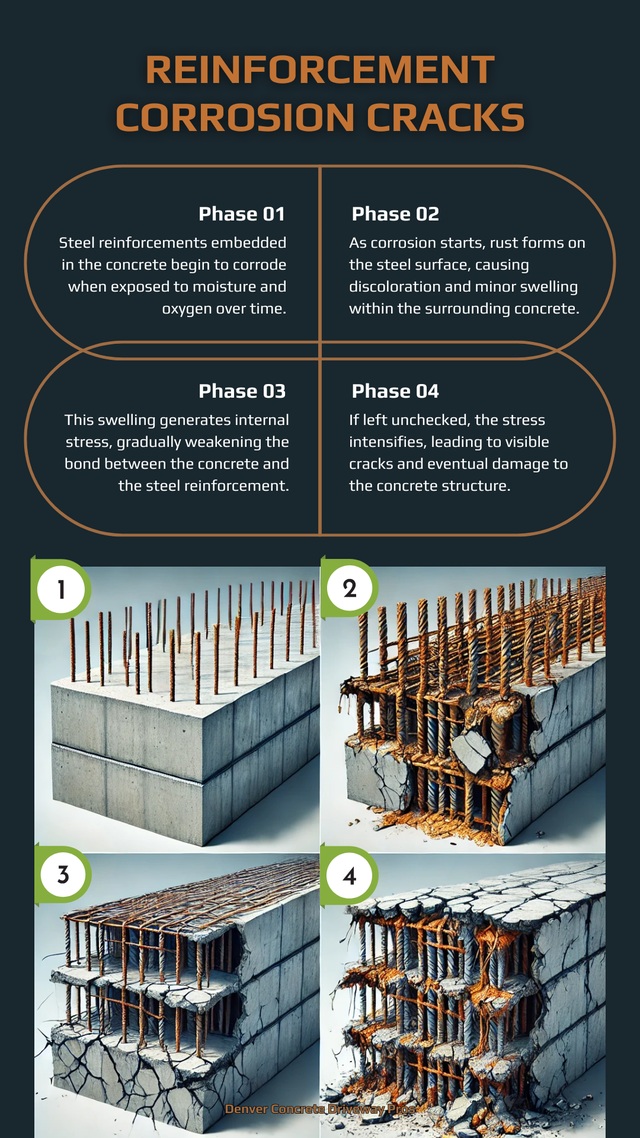

Reinforcement Corrosion Cracks (The Hidden Threat)

Steel reinforcements inside the concrete can corrode over time.

As the steel expands, it creates stress. That stress leads to cracking. Common causes include:

- Carbonation: When carbon dioxide lowers the concrete’s pH.

- Chloride Penetration: When salts or moisture seep in, reducing pH levels.

These cracks can cause the concrete to spall and break apart. That exposes the steel further.

How to Prevent Driveway Cracks

We like surprises. But not the cracking kind ones. Here’s how to not get those types of surprises:

- Start with Solid Prep: Compact the soil and use high-quality materials.

- Add Control Joints: These give concrete a place to crack neatly instead of randomly.

- Cure It Right: Let your concrete dry slowly. A rushed job invites trouble.

- Seal the Surface: Protect against water, oil, and temperature extremes.

- Control Tree Roots: Consider installing root barriers or choosing less invasive species.

- Prepare the Subgrade Thoroughly: Compact the soil and add a gravel layer to prevent settlement cracks.

- Monitor Reinforcement Placement: Make sure bars and mesh are positioned correctly during installation.

- Use Non-Reactive Aggregates: Test materials beforehand to ensure long-term stability.

- Inspect Often: Spot cracks early and deal with them before they grow.

- Pick the Pros: Work with professionals (like us!) who know what they’re doing.

When to Call Denver Concrete Driveway Pros

Dealing with driveway cracks? Don’t panic. Some small cracks are DIY-friendly. But others need professional care. If your driveway has large, deep, or growing cracks, we can help.

We specialize in repairing and replacing concrete driveways in Denver. With decades of experience, we’ll make your driveway look brand new and stand up to anything.

Final Thoughts - Don’t Let Cracks Win

Cracks in concrete driveways are common. But they’re not all created equal. Know what type of crack you’re dealing with.

Address it early. It can save you time and money. For expert advice and top-notch repair services, trust Denver Concrete Driveway Pros.

Contact Denver Concrete Driveway Pros today for a free consultation. And let’s keep your driveway strong and crack-free.