Expert Insights on Using Geopolymer Concrete for Driveways

Denver Concrete Driveways Pro are evolving, and the buzzword everyone’s talking about? Geopolymer concrete. Traditional concrete has been the backbone of construction for ages. But it’s far from perfect. The types of cracking depends on pressure. Leaving a hefty carbon footprint. And adding to environmental strain. It’s reliable. But at a cost.

Now imagine a smarter and greener alternative. Geopolymer concrete! The revolutionary material that’s rewriting the rules of construction.

But you don't only swap one material for another. Geopolymer concrete represents a leap forward. It is sustainable. Plus, it has incredible strength and durability.

Curious why so many experts are calling this the future of construction? Let’s explore what makes geopolymer concrete so revolutionary.

What Exactly Is Geopolymer Concrete?

Geopolymer concrete (GPC) is concrete’s smarter and greener sibling. Traditional concrete relies heavily on Portland cement. That is a major contributor to CO₂ emissions.

GPC ditches the cement. Instead, it uses industrial by-products. For example, fly ash, slag, and other aluminosilicate materials. These are activated by alkaline solutions. The result? A material with:

- 80-90% lower carbon emissions during production.

- Superior resistance to heat, chemicals, and physical wear.

- Longer lifespan compared to its cement-based counterpart.

Imagine using the same factories that produce fly ash—typically waste material from coal plants—to create a product that outperforms traditional concrete. Genius, right?

Why Are Experts Backing GPC for Driveways?

Industry veterans rave about geopolymer concrete for driveways, and here’s why:

1. Durability Like No Other

Geopolymer concrete thrives where traditional concrete falters. Whether your driveway needs to withstand heavy SUVs or fluctuating weather, GPC is a powerhouse. Its chemical composition makes it resistant to:

- Cracking under freeze-thaw cycles.

- Degradation from salt, oil spills, or acidic rain.

- Structural failure from constant vehicular stress.

In fact, studies show that geopolymer driveways can last decades longer. Longer than traditional ones when properly maintained.

2. Eco-Friendly Without Compromise

Concrete has an environmental footprint. It has long been a problem. Cement production alone accounts for 8% of global CO₂ emissions. By contrast, GPC repurposes industrial waste. This diverts millions of tons from landfills and slashes emissions. It’s a driveway that says, “I care about the planet.”

3. Cost-Efficiency Over Time

Yes, geopolymer concrete may have a higher initial cost, but its low maintenance needs and extended lifespan mean fewer repairs, replacements, and headaches. For homeowners who think long-term, GPC often saves money in the end.

4. Heat and Fire Resistance

Unlike traditional concrete, geopolymer concrete exhibits exceptional resistance to extreme temperatures. Driveways often endure scorching summers or accidental contact with hot substances, but GPC holds its structure even in high-heat environments.

This property makes it ideal for regions prone to wildfires or urban heat islands, offering homeowners added safety and durability.

5. Faster Setting Times

Geopolymer concrete sets significantly faster than traditional concrete, meaning less downtime during installation. For homeowners, this translates to a quicker return to using their driveway without compromising quality. Contractors also appreciate the time efficiency, enabling them to complete projects faster while maintaining excellent standards.

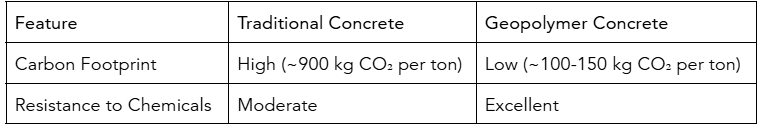

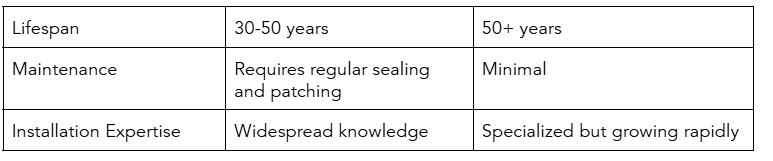

How Does GPC Compare to Traditional Concrete?

Here’s a quick side-by-side breakdown:

Challenges: Is It All Sunshine and Rainbows?

While geopolymer concrete is revolutionary. There are a few things to consider:

- Specialized Expertise Needed: Installing GPC requires skilled professionals who understand its unique chemical behavior. Not every contractor is equipped.

- Limited Availability: Depending on your region, finding geopolymer materials might involve extra research.

- Higher Upfront Cost: Although it pays off over time, the initial expense can deter budget-conscious homeowners.

Design Possibilities: More Than Just a Gray Slab

Geopolymer concrete isn’t limited to the dull, gray driveways you’ve seen before. Its versatility allows for:

- Custom Textures: Mimic the look of brick, cobblestone, or even wood.

- Color Variations: Unlike traditional concrete, GPC can incorporate pigments more effectively, offering vibrant finishes.

- Polished Looks: Go for sleek, modern aesthetics or rustic charm—the choice is yours.

How to Maintain a Geopolymer Driveway

GPC has a lot of standout features. One is its low-maintenance nature. Follow these tips to keep your driveway pristine:

- Routine Cleaning: Sweep and wash away dirt regularly.

- Occasional Sealing: While GPC is resistant to wear, sealing can enhance its longevity.

- Quick Repairs: In rare cases of damage, repairs are straightforward and often quicker than with traditional concrete.

The Future of Geopolymer Concrete

Sustainability is becoming a priority worldwide. So geopolymer concrete is not a passing trend. It’s the future. Architects, builders, and homeowners are increasingly opting for GPC. Plus, research into expanding its applications is booming. Experts predict it will play a pivotal role in green construction.

Countries like Australia and India are already integrating GPC into major infrastructure projects, including roads and bridges. The U.S. is catching up, with more suppliers and contractors getting on board.

Final Thoughts: Is GPC Right for Your Driveway?

Do you value durability, sustainability, and cutting-edge technology? Geopolymer concrete is worth every penny. It’s a driveway material that serves your home. It also benefits the planet. Sure, it might take a bit more effort. Like the right contractor and materials. But the rewards are undeniable.

Ready to make the switch? Contact us now for a free quote!